Manufacturing growth poses challenges for labour market

by ,http://vietnamnews.vn/society/481186/manufacturing-growth-poses-challenges-for-labour-market.html01 December 2018 Last updated at 06:59 AM

|

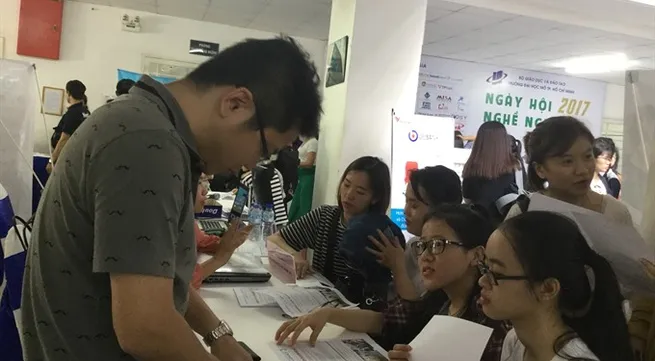

| Enterprises recruit students at a job fair held at HCM City Open University. —VNS/Photo Gia Lộc |

HCM CITY — Manufacturing’s growth potential is bringing both opportunities and challenges for the labour market, recruitment experts have said.

Gaku Echizenya, CEO of Navigos Group Vietnam, said: “Unless actions are taken to accelerate the technological transition, we risk losing our attractive profile in the eyes of foreign investors to other developing countries in the area.”

Navigos Group operates VietnamWorks, the executive search firm Navigos Search, and PRIMUS, a platform that provides exclusive C-level recruitment solutions.

“All in all, efforts made by businesses to invest in machinery and tools must be solidified by improving the quality of manpower,” he said.

Tamara Boonstra, director of Michael Page Vietnam, which specialises in recruiting middle to senior managers, said that many manufacturing plants were moving from China to Việt Nam as a result of government policies.

The challenge lies in preparing the Vietnamese workforce to meet the demands of the sector, Boonstra added.

According to an annual salary survey from professional recruitment firm Robert Walters, rising investment levels and new market entrants this year have led to a buoyant recruitment market, particularly in the manufacturing sector.

Last year, the entry of more multinational corporations into the country and the expansion of existing facilities led to continued growth in the manufacturing sector.

With favourable market conditions, this trend is expected to continue in 2018.

Demand was high for domestic candidates and Vietnamese nationals returning from overseas, as firms increasingly recognised the value of hiring talent with local and global skill sets.

Hiring managers also sought candidates who were fluent in speaking English and had experience of working overseas.

“To secure the best candidates in the market, we advise hiring managers to improve their employer value proposition and clearly outline the career development opportunities they can offer. They should provide ample training opportunities and regularly track performance,” the Robert Walters report said.

The Navigos Group’s report “The Labor Market in Manufacturing – Opportunities & Challenges in the 4.0 Era” found that 55 per cent of 200 employers answering the survey experienced a labour shortage this year

Thirty-five per cent of them said they lacked a qualified workforce, and the low rate of application remained a challenge.

According to the report, manufacturing firms were struggling to attract young candidates for several reasons, including “career trends of young candidates” and “weak employer brand”.

“In response, 32 per cent of firms shared their plan to strengthen their employer brands to remedy the situation,” the report said.

Despite having a stronger commitment, manufacturing staff changed jobs for various reasons related to the nature of the industry.

On top of an unsatisfactory salary, compensation and benefits, the location of suburban workplaces far from city centers and a polluted (air, noise) working environment were among the top five reasons for quitting, the report said.

Thirty-nine per cent of employers agreed that remote workplaces restricted their recruitment results.

Solutions

To alleviate manpower shortage in both quantity and quality, manufacturing firms are engaged in various forms of collaboration, according to the report.

Partnering with training facilities to improve or customise the curriculum to meet recruitment needs is common.

Traditional methods such as on-the-job training, in-house training or in-service training for subordinates are common in manufacturing businesses, reported by over 43 per cent of 3,200 surveyed candidates currently working or seeking jobs in the sector and 83 per cent of employers.

On the other hand, online training is rare, as only 5 per cent of employers and 4 per cent of staff confirmed its application in their workplaces.

In terms of training agendas, 64 per cent of firms said their priorities were hard skills, compared to soft skills and foreign languages.

In addition, it was common for employers to recruit people with relevant background knowledge and then provide training to improve their technical skills.

Employees, in turn, evaluated the staff at their firms, saying they were not proactive and lacked technical knowledge, discipline, and a learning attitude.

According to the report, 46 per cent of firms were automating up to 30 per cent of all manufacturing processes, and 32 per cent had achieved 30 per cent to 70 per cent automation.

Employees also showed an active attitude towards change by strengthening technical knowledge and skills, as well as language competency.

While recognising that the technological transition would have the gravest impact on blue-collar workers, both employees and employers shared the opinion that “automation is inevitable in manufacturing”.—VNS