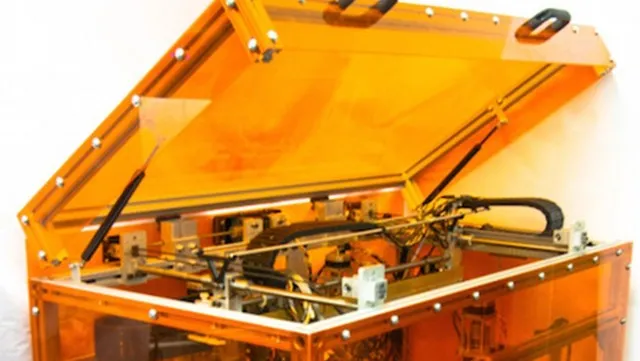

Newly developed 3D printer can print with ten different materials

Up until now, most uses of 3D printers have been to create plastic objects, although technology is advancing at such a pace that scientists have managed to print metal , concrete and even glass . But one persistent problem has been printing multiple materials from the same machine. Now researchers at MIT have announced they’ve managed to build a printer that can print an unprecedented 10 different materials.

Not only that, but the “MultiFab” 3D printer will make the process better, cheaper, and more user-friendly, claim its creators. Working at an impressive resolution of just 40 microns, it is also able to quite amazingly self-calibrate and self-correct. This means that if, during printing, the machine realizes that things aren’t quite level, it can go back and add material to where it has decided it's necessary. Not only that, the printer is also able to print around objects, such as smartphones, and even print a lens over an LED light.

“The platform opens up new possibilities for manufacturing, giving researchers and hobbyists alike the power to create objects that have previously been difficult or even impossible to print,” explains Javier Ramos, one of the co-authors of the paper accepted at the SIGGRAPH computer graphics conference. Working out of MIT’s Computer Science and Artificial Intelligence Lab (CSAIL), they’ve built the machine for just $7,000 (£4,500) – way less than the $250,000 (£160,000) they claim current multi-material printers cost, and that’s just with three materials.

The main issue with multi-material printers is that each material requires different conditions (such as temperature or pressure) in order to be printed. Most current machines also work using “extrusion” technologies, effectively ejecting the plastic through syringes. MultiFab, on the other hand, “mixes microscopic droplets of photopolymers together that are then sent through inkjet printheads similar to the ones you see in office printers,” says a statement from CSAIL. It is also due to this method that they can get such high resolution.

The printer currently uses materials that are all “UV-curable photopolymers” with different properties. For example, it could create something made from a solid polymer and from a flexible plastic. The researchers hope that this technology will be useable by everyone, from corporations and manufacturers to a simple hobbyist.

“Picture someone who sells electric wine-openers, but doesn’t have $7,000 to buy a printer like this. In the future they could walk into a FedEx with a design and print out batches of their finished product at a reasonable price,” says Ramos. “For me, a practical use like that would be the ultimate dream".

Tags: